>Definition of Bridge

• A bridge is a structure providing passage over an obstacle without closing the way beneath. The required

passage may be for a road, a railway, pedestrians, a canal or a pipeline. The obstacle to be crossed may be a

river, a road, railway or a valley.

• In other words, bridge is a structure for carrying the road traffic or other moving loads over a depression or

obstruction such as channel, road or railway.

>COMPONENTS OF A BRIDGE

The bridge structure comprises of the following parts.

* Superstructure or Decking

This includes slab, girder, truss, etc. This bears the load passing over it and transmits the forces caused by the same

to the substructures.

* Bearings

The bearings transmit the load received from the decking on to the substructure and are provided for distribution of

the load evenly over the substructure material which may not have sufficient bearing strength to bear the

superstructure load directly

* Substructure

This comprises piers and abutments, wing walls or returns and their foundation.

* Piers and Abutments

The intermediate bridge supports are called piers and the main function of piers is to divide the total length of bridge

in to suitable spans with minimum obstruction to the river.

Abutments are end support of a bridge super structure its function is to finish up to bridge so that it can be put for

use. And also to transmit the reactions of superstructure to the foundations

* Wing walls

These are provided as extension of the abutments to retain the earth of approach bank which otherwise has a

natural angle of repose.

* Foundation

This is provided to transmit the load from the piers or abutments and wings or returns to and evenly distribute the

load on to the strata. This is to be provided sufficiently deep so that it is not affected by the scour caused by the flow

in the river and does not get undermined. While the above mentioned are structurally operational parts, for safety

hand rails or parapets, guard rails or curbs are provided over the decking in order to prevent vehicle or user from

falling into the stream or for the separation of traffic streams.

>CLASSIFICATION OF BRIDGES

• Bridges may be classified in many ways, as below.

According to the flexibility of superstructure as fixed span bridges or movable bridges.

• Fixed span superstructure

In case of fixed span superstructure, the superstructure remains in a fixed position and most of the bridges

are of this category.

• Movable span bridges

In case of movable span superstructure, the superstructure is lifted or moved with the help of some suitable

arrangement.

• According to the position of bridge floor relative to the formation level and the highest flood

discharge as deck bridges, through bridges or semi through bridges.

• Deck bridges

• Bridges may be classified in many ways, as below.

According to the flexibility of superstructure as fixed span bridges or movable bridges.

• Fixed span superstructure

In case of fixed span superstructure, the superstructure remains in a fixed position and most of the bridges

are of this category.

• Movable span bridges

In case of movable span superstructure, the superstructure is lifted or moved with the help of some suitable

arrangement.

• According to the position of bridge floor relative to the formation level and the highest flood

discharge as deck bridges, through bridges or semi through bridges.

• Deck bridges

If it is possible to accommodate the superstructure of bridge between these two levels with suitable allowance for clearance as shown in figure it is called Deck Bridge

• Through Bridges

Sometimes the difference between the formation level and H.F.L is not sufficient to accommodate the superstructure of bridge. In such cases the super structure projects above the formation level as shown in figure is called through bridge

• Semi-Through Bridges

When the super structure of bridge projects partly above the formation level and partly below the formation level,

as shown in figure it is called as semi through bridge.

> According to the inter-span relations Bridges are classified in to three categories

• Simply supported

Generally width of bridge is divided into number of individual spans. For each span, the load carrying member is

simply supported at both ends.

• Continuous

• In continuous bridges spans are continuous over two or more supports. In continuous bridges the bending moment anywhere in the span is considerably less than that in case of simply supported span. Thus continuous span bridges have considerable saving compared to simply supported bridge Cantilever A cantilever bridge is formed of cantilevers projecting from supporting piers. The ends of a cantilever bridge are treated as fixed. A cantilever bridge combines the advantages of a simply supported span and a continuous span. For long spans and deep valleys and at places where it will not be practicable to use centering, cantilever bridges are more suitable. They are suitable in case of uneven settlement of foundation. The construction of a cantilever bridge may either be of simple type or of balanced type.

Cantilever Bridge with simple construction

In case of cantilever bridge with balanced type of construction, hinges are provided at the points of contra flexure of a continuous span and an intermediate simply supported span is suspended between two hinges.

• According to the form or type of superstructure as arch, beam, truss, slab, rigid frame or suspension

bridges.

• Slab

• Beam

bridges.

• Slab

• Beam

• Girder

• Truss

The girder/beam as well as the truss can be made up of timber, steel or concrete, or can be made up of combination of steel and concrete.

The girder/beam as well as the truss can be made up of timber, steel or concrete, or can be made up of combination of steel and concrete.

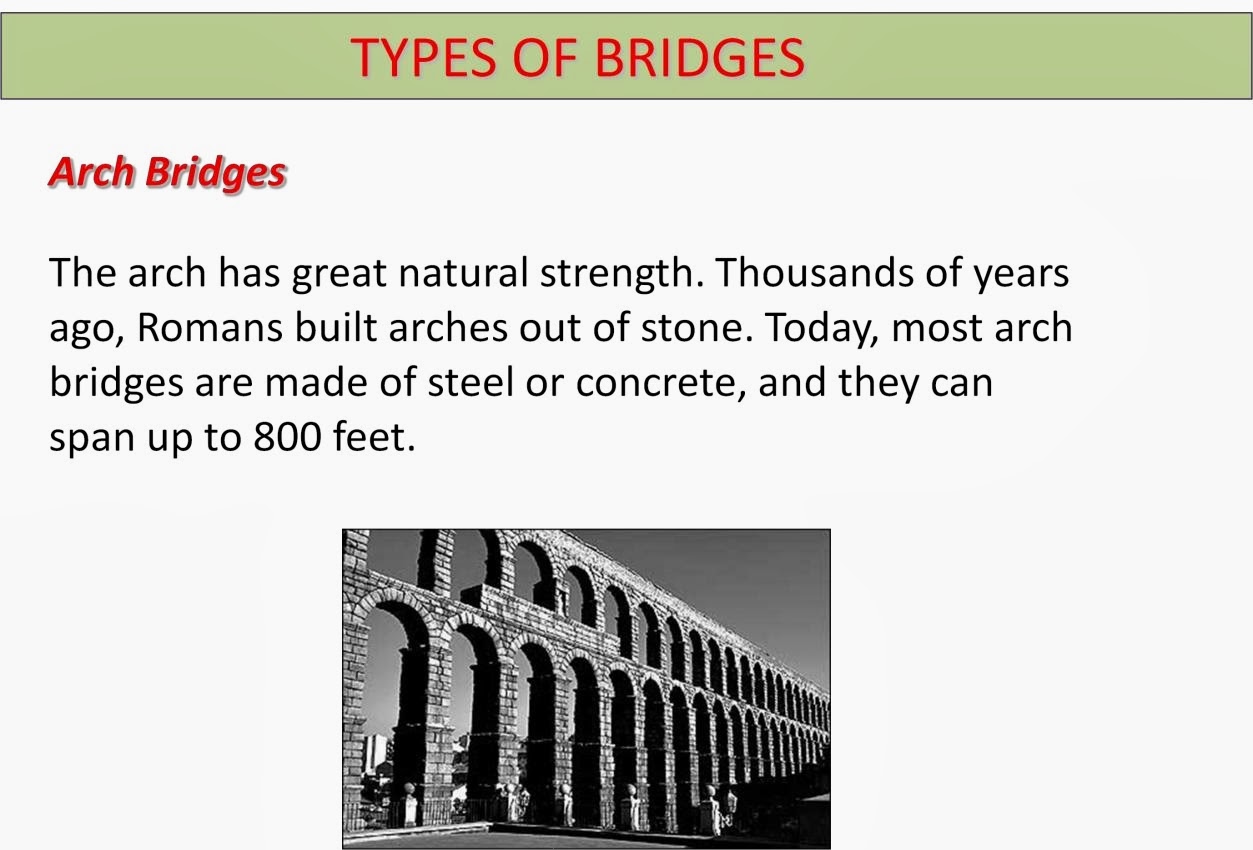

• Arch

• Suspension

Suspension bridges are made up of high tensile steel cables strung in form of catenaries to which the deck is attached by steel suspenders, which are mainly made up of steel rods/members/cables.

Suspension bridges are made up of high tensile steel cables strung in form of catenaries to which the deck is attached by steel suspenders, which are mainly made up of steel rods/members/cables.

• Cable stayed

Cable-stayed bridges are similar to the suspension bridges excepting that there will be no suspenders in the cable stayed bridges and a number of these can be of masonry,concrete or steel.

Cable-stayed bridges are similar to the suspension bridges excepting that there will be no suspenders in the cable stayed bridges and a number of these can be of masonry,concrete or steel.

• Various economical span ranges for these types generally adopted are:

Arch : For small spans of 3 to 15m in masonry, steel arch up to 519m and concrete arches up to 305m spans.

Slabs : Up to 9m.

Girders and beams : 10 to 60m (exception up to 250m in continuous construction).

Trusses : 30 to 375m simply supported and up to 550m with cantilevered combination.

Suspension Bridges : Over 500m up to 1400m.

Cable Stayed : 300 to 600m.

• According to the materials of construction used for superstructure as cement concrete, prestressed

concrete, steel, masonry, iron, timber or composite bridges.

The earliest form of materials used for construction of bridges was first stone and later brick. The masonry bridges are used for short spans and according to availability of material and skilled labour. They are mainly of arch type of bridges. The next form of construction was Timber Bridge in which timber was used for spanning the gap and also for supporting the beams. Timber bridges are used for short spans, light loads and for use as temporary and unimportant bridges. With the invention and development of concrete, bridges are being built entirely with concrete, either reinforced or prestressed or a combination of both for superstructure. Many combination of above types are also possible. The common examples of composite construction are

• Concrete beams reinforced with steel bars.

• Precast prestressed concrete girder with cast-in-situ RCC slab.

Following are the advantages of composite bridges.

• It leads to reduction in deflection and vibrations.

• It leads to speed in construction.

• It proves to be economical.

• It results in better quality control.

• The cost of formwork is reduced.

• The cost of foundations for abutments is reduced.

• The cost of transportation is minimized.

• The overall depth of beam for a composite construction is reduced and

• It leads to savings in lengths of approaches.

• Table shows the maximum spans up to which a particular type of bridge can be recommended.

Sr. Type Maximum

No.

1 RCC arch bridge 200 m

2 RCC bow-string girder bridge 45 m

3 RCC cantilever bridges with balanced type

4 RCC continuous bridge 45 m

5 RCC deck type girder bridge 20 m

6 RCC filled spandrel fixed arch bridge 35 m

7 RCC open spandrel rib type bridge 60 m

8 RCC portal frame bridge 15 m

9 Prestressed concrete arch bridge 150 m

10 Prestressed concrete continuous bridge 110 m

11 Prestressed concrete girder bridge simply 55 m span 30 m supported

12 Steel arch bridge 500 m

13 Steel bow-string girder bridge 240 m

14 Steel cable suspension bridge 1200 m

15 Steel plate girder 30 m

16 Steel rolled beam bridge 10 m

17 Steel truss bridge 180 m

Sr. Type Maximum

No.

1 RCC arch bridge 200 m

2 RCC bow-string girder bridge 45 m

3 RCC cantilever bridges with balanced type

4 RCC continuous bridge 45 m

5 RCC deck type girder bridge 20 m

6 RCC filled spandrel fixed arch bridge 35 m

7 RCC open spandrel rib type bridge 60 m

8 RCC portal frame bridge 15 m

9 Prestressed concrete arch bridge 150 m

10 Prestressed concrete continuous bridge 110 m

11 Prestressed concrete girder bridge simply 55 m span 30 m supported

12 Steel arch bridge 500 m

13 Steel bow-string girder bridge 240 m

14 Steel cable suspension bridge 1200 m

15 Steel plate girder 30 m

16 Steel rolled beam bridge 10 m

17 Steel truss bridge 180 m

> According to the method of clearance for navigation as bascule, lift, swing or transporter bridges.

• Movable – bascule bridges

In bascule bridges, the main girders are lifted together with deck about the hinge provided on one end of the span.

Depending upon the width of channel, the bascule bridge may either be single or double.

• Movable – bascule bridges

In bascule bridges, the main girders are lifted together with deck about the hinge provided on one end of the span.

Depending upon the width of channel, the bascule bridge may either be single or double.

• Movable – swing bridges

In swing bridges, the girders and deck can be swung about its middle over the middle pier, clearing the span on either side for passage ship.

In swing bridges, the girders and deck can be swung about its middle over the middle pier, clearing the span on either side for passage ship.

• Movable – lift bridges

In this case, gantries are provided at the piers at either end of the span and the entire girder and the floor system is lifted up by a hydraulic arrangement to the extent required for free passage of the ship.

In this case, gantries are provided at the piers at either end of the span and the entire girder and the floor system is lifted up by a hydraulic arrangement to the extent required for free passage of the ship.

• Transporter

In case of transporter bridges, a moving cage is suspended from an overhead truss with the help of cable or wire ropes. The overhead truss rests on two towers and it contains rails for cage to roll. This type of bridge is used within a harbour area to provide an arrangement for shifting of men and materials across a channel

> According to the expected utility period of service 1) temporary bridges. 2) Permanent Bridges

• Temporary bridges

The temporary bridges are defined as structures, which are constructed to cross a river or a stream in place of permanent works. Such bridges are useful when it is not possible to construct a permanent bridge due to shortage of money, time, good materials or skilled labour. The temporary bridges are often constructed on diversions during the reconstruction of an existing permanent bridge. The useful life of a temporary bridge is estimated as about 10 years.

• Permanent bridges

The permanent bridges are defined as structures, which are constructed to cross a river or a stream permanently.

• According to the function as road, railway, road-cum-railway or pipeline bridges.

• Temporary bridges

The temporary bridges are defined as structures, which are constructed to cross a river or a stream in place of permanent works. Such bridges are useful when it is not possible to construct a permanent bridge due to shortage of money, time, good materials or skilled labour. The temporary bridges are often constructed on diversions during the reconstruction of an existing permanent bridge. The useful life of a temporary bridge is estimated as about 10 years.

• Permanent bridges

The permanent bridges are defined as structures, which are constructed to cross a river or a stream permanently.

• According to the function as road, railway, road-cum-railway or pipeline bridges.

> According to the method of connections adopted in steel bridges as riveted, welded or pin-connected bridges.

Majority of steel bridges are of riveted type, welded type is recently used.

• Pin-connected

• Riveted

• Riveted connections are proved to be more rigid and responsible for secondary stresses. ·

• Welded

Majority of steel bridges are of riveted type, welded type is recently used.

• Pin-connected

• Riveted

• Riveted connections are proved to be more rigid and responsible for secondary stresses. ·

• Welded

> According to the length of span as culvert, minor bridges, major bridges or long span bridges.

• Culverts (less than 6m)

• Culvert is a bridge having a gross length of six meters or less between the faces of abutments or extreme vent way boundaries and measured at right angles thereto.

·Minor bridge (6 to 30m)

·Major bridge (above 30m)

·Long span bridge (above 120m)

• According to the level of crossing of highways and railways as over bridges or under bridges.

• Over bridge

When the highway bridge is carried over or under the highway by means of bridge, the bridge is known as over bridge.

• Under bridge

When the highway is carried under the railway track by means of bridge is known as the under bridge.

> According to the alignment as straight or skew bridges.

PRELIMARY DATA TO BE COLLECTED FOR BRIDGE CONSTRUCTION

• Availability of Electric Power

• Availability of materials of construction

• Availability of skilled and unskilled labour for different jobs of bridge construction

• Details of existing bridge on the same river

• Characteristics and hydraulic data of river

• Means of transport to carry the materials

• Name of river and location of bridge site

• Nature of road traffic at bridge site

• Possibility of earthquake disturbances

• Present and future traffic

• Sub soil conditions

• Safety and aesthetic considerations

>SELECTION OF BRIDGE SITE

• Connection with roads

The bridges are constructed to connect the roads on either side of a river .The approach should avoid the cutting

across the built up area or religious structures because the acquisition of the land and structures will be expensive

and time consuming.

• Firm Embankments

The embankments on the upstream and downstream side of bridge site should be firm, high, permanent, solid,

and straight

• Foundations

The nature of soil at the bed of river at bridge site should be such that good foundations are available at

reasonable depth for sub structure of bridge.

• Velocity of flow

It is very important to check that the velocity of flow at bridge site is proper. If the velocity of flow is less than a

particular value, the silting will occur and on other hand if it is more than a particular value the scouring will occur.

As a matter the velocity of flow at bridge site should be Non silting & Non scouring velocities

• Width of river

It is quite evident that the width of river indicates length of bridge. It is desirable to have a minimum width of

river at bridge site. Smaller is the width cheaper is the bridge.

PRELIMARY DATA TO BE COLLECTED FOR BRIDGE CONSTRUCTION

• Availability of Electric Power

• Availability of materials of construction

• Availability of skilled and unskilled labour for different jobs of bridge construction

• Details of existing bridge on the same river

• Characteristics and hydraulic data of river

• Means of transport to carry the materials

• Name of river and location of bridge site

• Nature of road traffic at bridge site

• Possibility of earthquake disturbances

• Present and future traffic

• Sub soil conditions

• Safety and aesthetic considerations

>SELECTION OF BRIDGE SITE

• Connection with roads

The bridges are constructed to connect the roads on either side of a river .The approach should avoid the cutting

across the built up area or religious structures because the acquisition of the land and structures will be expensive

and time consuming.

• Firm Embankments

The embankments on the upstream and downstream side of bridge site should be firm, high, permanent, solid,

and straight

• Foundations

The nature of soil at the bed of river at bridge site should be such that good foundations are available at

reasonable depth for sub structure of bridge.

• Velocity of flow

It is very important to check that the velocity of flow at bridge site is proper. If the velocity of flow is less than a

particular value, the silting will occur and on other hand if it is more than a particular value the scouring will occur.

As a matter the velocity of flow at bridge site should be Non silting & Non scouring velocities

• Width of river

It is quite evident that the width of river indicates length of bridge. It is desirable to have a minimum width of

river at bridge site. Smaller is the width cheaper is the bridge.

>NUMBER OF SPAN

The number of spans for a bridge should be carefully decided by considering all aspects of bridge such as cost of

construction, nature of flow, importance of bridge, material available etc.

Following important points are to be remembered while deciding the number of spans for a bridge.

• Alternative proposals

It is desirable to prepare 3 or 4 alternative proposals of number of spans for a bridge and then the one which is

most economical and suitable should be recommended

• Foundation for piers

The foundations available for piers also play an important role in determining the number of spans for a bridge.

The piers should rest on firm and stable soil.

• Odd numbers of spans

It is desirable to adopt odd numbers of spans of a bridge. The velocity of flow is the highest at centre of length of

bridge. An odd number of spans will provide an opening in the centre of length of bridge.

• Span

It is desirable to have span as large as possible. In other words the number of spans should be restricted to as few

as possible especially in mountainous regions . On other hand the small spans will require more piers and hence the

waterway under the bridge will be seriously obstructed.

The number of spans for a bridge should be carefully decided by considering all aspects of bridge such as cost of

construction, nature of flow, importance of bridge, material available etc.

Following important points are to be remembered while deciding the number of spans for a bridge.

• Alternative proposals

It is desirable to prepare 3 or 4 alternative proposals of number of spans for a bridge and then the one which is

most economical and suitable should be recommended

• Foundation for piers

The foundations available for piers also play an important role in determining the number of spans for a bridge.

The piers should rest on firm and stable soil.

• Odd numbers of spans

It is desirable to adopt odd numbers of spans of a bridge. The velocity of flow is the highest at centre of length of

bridge. An odd number of spans will provide an opening in the centre of length of bridge.

• Span

It is desirable to have span as large as possible. In other words the number of spans should be restricted to as few

as possible especially in mountainous regions . On other hand the small spans will require more piers and hence the

waterway under the bridge will be seriously obstructed.

>CHOICE OF BRIDGE TYPE

• Some of the aspects which influence the choice to be made between different types of bridges are as

follows.

• Availability of Funds

If the fund available is not sufficient to put up a high level bridge, the small submersible bridge should be

recommended.

• Climatic conditions

If the environmental conditions are unsuitable certain types of bridge cannot be constructed. if the climatic

conditions at bridge site are likely to accelerate the process of corrosion, the steel trusses cannot be adopted.

• Economy in construction

If the river is wide the economy in construction can be achieved by putting up a road cum rail bridge in two tiers

instead of two separate bridges.

• Foundations

The soil conditions at bridge site may bring down the possible alternatives and under such circumstances the

choice of a particular type of bridge is to be made from such limited alternatives only.

• Navigational requirements

If it is desired to have more vertical clearance for satisfying the navigational requirements of the community

certain types of bridges such as arch bridges, suspension bridges will only have to be selected.

• Type of Traffic

• The steel trusses are preferable to the suspension bridges for railway traffic. The traffic forecast is made for

the project as such and it will help in determining the size of bridge i.e. numbers of lanes or tracks to be

provided. Future traffic is also to be taken in to considerations.

• Some of the aspects which influence the choice to be made between different types of bridges are as

follows.

• Availability of Funds

If the fund available is not sufficient to put up a high level bridge, the small submersible bridge should be

recommended.

• Climatic conditions

If the environmental conditions are unsuitable certain types of bridge cannot be constructed. if the climatic

conditions at bridge site are likely to accelerate the process of corrosion, the steel trusses cannot be adopted.

• Economy in construction

If the river is wide the economy in construction can be achieved by putting up a road cum rail bridge in two tiers

instead of two separate bridges.

• Foundations

The soil conditions at bridge site may bring down the possible alternatives and under such circumstances the

choice of a particular type of bridge is to be made from such limited alternatives only.

• Navigational requirements

If it is desired to have more vertical clearance for satisfying the navigational requirements of the community

certain types of bridges such as arch bridges, suspension bridges will only have to be selected.

• Type of Traffic

• The steel trusses are preferable to the suspension bridges for railway traffic. The traffic forecast is made for

the project as such and it will help in determining the size of bridge i.e. numbers of lanes or tracks to be

provided. Future traffic is also to be taken in to considerations.

>REQUIREMENTS OF AN IDEAL BRIDGE

An ideal bridge should fulfill the following requirements.

• It should be efficient and effective

• It should be economical

• It should save the intended function with utmost safety and convenience.

An ideal bridge should fulfill the following requirements.

• It should be efficient and effective

• It should be economical

• It should save the intended function with utmost safety and convenience.

>FOUNDATIONS

• The foundations are required to distribute equally and uniformly the total load of the bridge on the soil.

• Essentials requirements of a good foundation

• Location

The foundation structure should be so located that it is able to resist any unexpected future influence which may

adversely effect its performance

• Stability

The foundation structure should be stable or safe against any possible failure

• Settlement

The foundation structure should not settle or deflect to such an extent so as to impair its usefulness.

• The foundations are required to distribute equally and uniformly the total load of the bridge on the soil.

• Essentials requirements of a good foundation

• Location

The foundation structure should be so located that it is able to resist any unexpected future influence which may

adversely effect its performance

• Stability

The foundation structure should be stable or safe against any possible failure

• Settlement

The foundation structure should not settle or deflect to such an extent so as to impair its usefulness.

>GENERAL PRINCIPLES OF DESIGN OF BRIDGE FOUNDATIONS

• Following two factors influence the design of bridge foundations

• Bearing capacity of soil

The bridge foundations should be taken to such a depth that the soil at that depth has sufficient safe bearing

capacity to withstand the load coming upon it without any settlement.

• Scour

The term scour is used to indicate the increase in depth in vertical direction of the bed of river. Such increase in

depth mainly occurs due to current of flowing water, bed material, discharge, bed slope etc.

• Following two factors influence the design of bridge foundations

• Bearing capacity of soil

The bridge foundations should be taken to such a depth that the soil at that depth has sufficient safe bearing

capacity to withstand the load coming upon it without any settlement.

• Scour

The term scour is used to indicate the increase in depth in vertical direction of the bed of river. Such increase in

depth mainly occurs due to current of flowing water, bed material, discharge, bed slope etc.

>TYPES OF FOUNDATIONS

• There are three types of bridge foundations

• Spread foundations

They are also called as open foundations as the construction is carried out in open excavation. As the work is

carried out in open these types of foundations are adopted where depth of water is not more and good soil is

available at shallow depth.

• Pile Foundations

The term pile foundation is used to describe a construction for the foundation of bridge piers which in turn is

supported on the piles. This types of foundation are adopted where the loose soil extend to greater depth. The piles

are driven vertically or in near vertical position.

• Coffer dams

It is a temporary structure which is constructed so as to remove water from an area and make it possible to carry

on the construction work under reasonably dry conditions.

• Caisson

It is a structure which is sunk through ground or water to exclude water and semi fluid material during the

process of excavation of foundations and which subsequently becomes an integral part of the sub structure

• There are three types of bridge foundations

• Spread foundations

They are also called as open foundations as the construction is carried out in open excavation. As the work is

carried out in open these types of foundations are adopted where depth of water is not more and good soil is

available at shallow depth.

• Pile Foundations

The term pile foundation is used to describe a construction for the foundation of bridge piers which in turn is

supported on the piles. This types of foundation are adopted where the loose soil extend to greater depth. The piles

are driven vertically or in near vertical position.

• Coffer dams

It is a temporary structure which is constructed so as to remove water from an area and make it possible to carry

on the construction work under reasonably dry conditions.

• Caisson

It is a structure which is sunk through ground or water to exclude water and semi fluid material during the

process of excavation of foundations and which subsequently becomes an integral part of the sub structure

>LOADING ON BRIDGES

• A bridge is to be designed for the worst effects produced by various forces, loads and stresses which are

acting on it simultaneously.

• Following are the various such forces, loads and stresses acting on a bridge.

• Buoyancy Pressure

The effect of buoyancy is considered in the design of bridge only if the strata of soil are permeable.

• Centrifugal Forces

When a road or railway bridge is situated on a curve, the effect due to centrifugal force is to be considered in

design.

• Dead Load

It indicates the load of structure itself.

• Deformation Stresses

Any bending stress which is developed in a steel member either due to vertical deflection or rigidity of joints is

called Deformation Stresses. It is to be taken for steel bridges only.

• Earth Pressure

The components of bridge which are required to retain earth should be designed for suitable earth pressure.

• Impact Load

The stresses developed due to fast moving heavy vehicles over uneven surfaces in case of road bridges is called

stress due to impact.

• Live Load

This are load coming on the bridges due vehicles goods etc.

• Seismic Load

When a bridge is situated in a locality which is likely to be affected by earthquakes, necessary allowance is to

be made in design of bridge for seismic load.

• Temperature variation forces

Due to variation in temperature the length of the structure is effected. If this changes are restrained the

temperature stresses are developed.

• Water Pressure

The portion of bridge which is submerged in running water is designed for horizontal forces of water current.

• Wind Load

The wind load is directly proportional to the square of the velocity and it is expressed as P=KV2

• A bridge is to be designed for the worst effects produced by various forces, loads and stresses which are

acting on it simultaneously.

• Following are the various such forces, loads and stresses acting on a bridge.

• Buoyancy Pressure

The effect of buoyancy is considered in the design of bridge only if the strata of soil are permeable.

• Centrifugal Forces

When a road or railway bridge is situated on a curve, the effect due to centrifugal force is to be considered in

design.

• Dead Load

It indicates the load of structure itself.

• Deformation Stresses

Any bending stress which is developed in a steel member either due to vertical deflection or rigidity of joints is

called Deformation Stresses. It is to be taken for steel bridges only.

• Earth Pressure

The components of bridge which are required to retain earth should be designed for suitable earth pressure.

• Impact Load

The stresses developed due to fast moving heavy vehicles over uneven surfaces in case of road bridges is called

stress due to impact.

• Live Load

This are load coming on the bridges due vehicles goods etc.

• Seismic Load

When a bridge is situated in a locality which is likely to be affected by earthquakes, necessary allowance is to

be made in design of bridge for seismic load.

• Temperature variation forces

Due to variation in temperature the length of the structure is effected. If this changes are restrained the

temperature stresses are developed.

• Water Pressure

The portion of bridge which is submerged in running water is designed for horizontal forces of water current.

• Wind Load

The wind load is directly proportional to the square of the velocity and it is expressed as P=KV2

No comments:

Post a Comment